At Green Energy Systems, engineering means more than just design. We develop practical, high-efficiency solutions tailored for biomass, waste and energy production. With a focus on functionality, long-term performance and integration, our team turns ideas into complete, working systems — built to last.

-

CHP plants

Power and Heat. One Source.

Combined heat and power from biomass ensures reliable, low-cost energy for heat-demanding industries.

-

Dryers

Efficient Drying. Compact Design.

Fully automated thin-layer dryers for biomass and waste—energy-efficient and space-saving.

-

Boilers

Biomass boilers

Efficient combustion, simple maintenance, and fuel flexibility — built for real heat needs.

-

Conveyors

Conveyors and Moving Floors

Engineered to keep material flow steady, safe, and unstoppable — even in heavy-duty conditions.

-

Metalworking

Metalworking That Delivers

From sheet to structure — we shape steel for real industry needs.

What we offer

Integrated Energy Solutions from Biomass and Waste

At Green Energy Systems, we design, manufacture, and install advanced equipment for renewable energy production.

Biomass Dryers

Efficient drying solutions for various bulk materials.

Conveyors and Moving Floors

Modular systems for bulk material handling.

Integrated Energy Solutions and biomass handling systems from Biomass and Waste

At Green Energy Systems, we design, manufacture, and install advanced equipment for renewable energy production.

Combined Heat and Power (CHP) Plants

Utilizing wood and waste to generate electricity and heat simultaneously.

Hydraulic driven units

Robust hydraulic solutions for biomass transport, compaction, and automation.

Combined Heat and Power (CHP) Plants

Biomass CHP technology delivers high-efficiency power and heat from renewable, locally sourced fuels.

CHP

Combined Heat and Power (CHP) is a way to produce electricity and heat at the same time in one process. It uses one fuel source to generate both forms of energy, making the system more efficient compared to separate production.

Biomass as a Renewable Energy Source

Biomass has become one of the most common sources of renewable energy. Due to its low cost and wide availability, it is extensively used, especially in Combined Heat and Power (CHP) plants.

What is Combined Heat and Power (CHP)?

Combined Heat and Power (CHP) refers to the simultaneous production of electricity and heat within a single thermodynamic cycle. This process can utilize solid biomass, gas, or liquid fuels as input.

Biomass in CHP Plants

In biomass CHP plants, biomass serves as the primary fuel source. Often, it is sourced directly from byproducts of existing production processes, making it a highly efficient and sustainable energy solution.

Applications of CHP

CHP systems are used across various sectors, including:

- District heating plants

- Wood processing plants

- Agricultural product processing facilities

- Waste processing plants

These facilities not only require both heat and electricity but often have biomass readily available as a byproduct of their own operations.

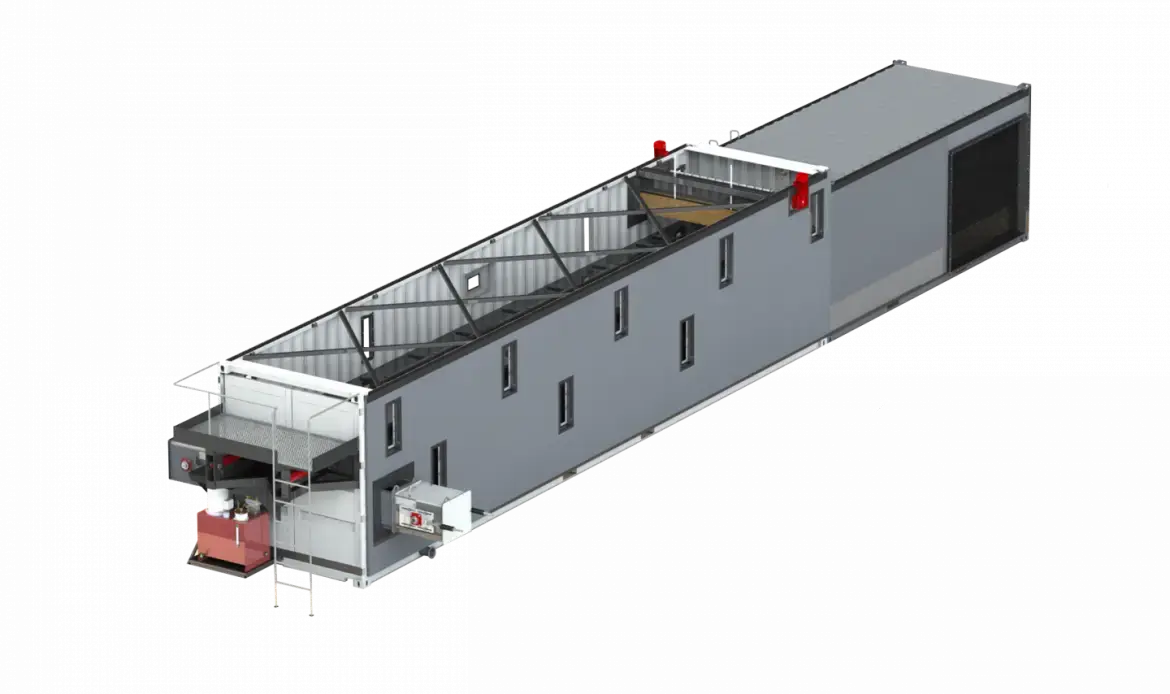

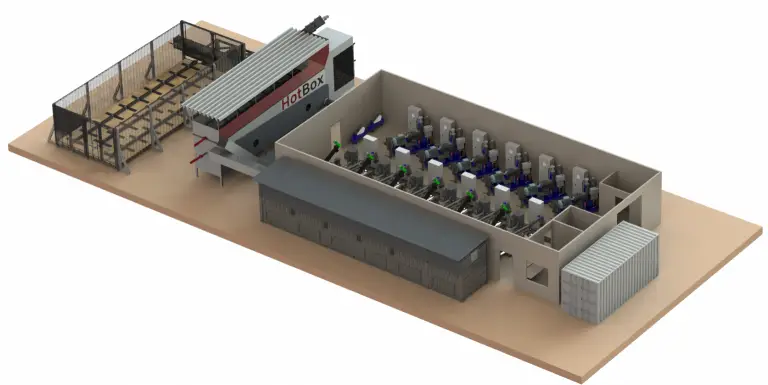

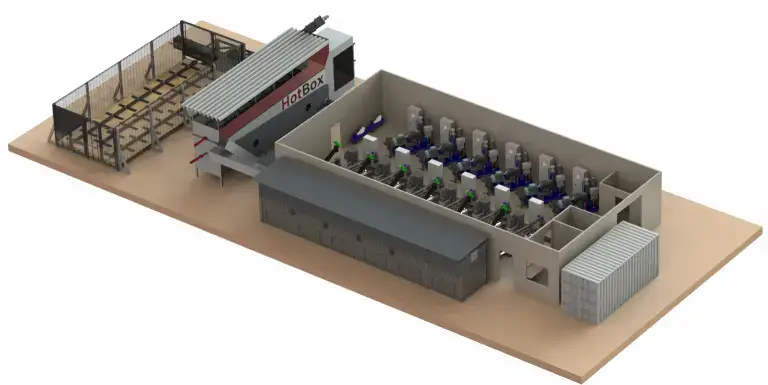

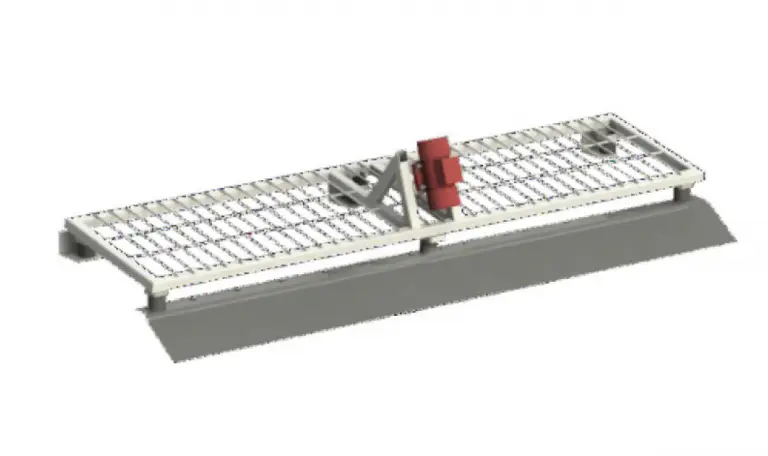

Dryers

Biomass & Waste To Energy dryers

Dryers

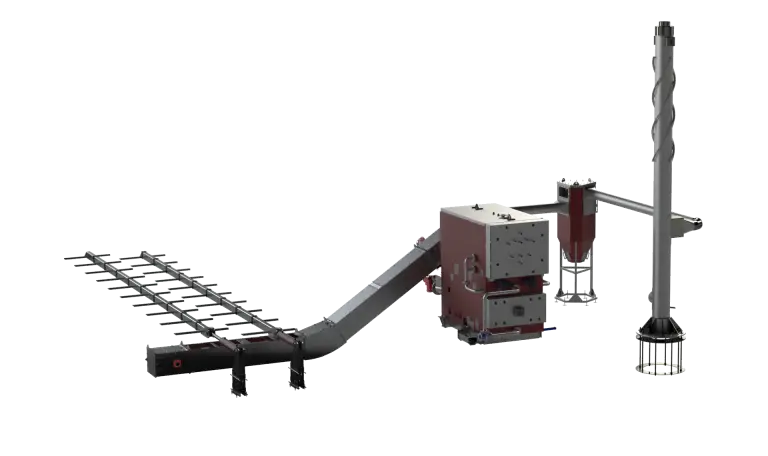

Hotbox dryers are fully automated systems designed for efficient drying of biomass, RDF, SRF waste, wastewater sludge and wood chips. With compact construction and robust design, these dryers are ideal for industrial applications where space is limited, and consistent drying performance is required. All necessary components are integrated into one container, making the system easy to install and operate.

Applications

Dryers are used for drying:

Biomass

Refuse-derived fuel (RDF)

Solid recovered fuel (SRF)

Wastewater sludge

Wood chips

Design

The dryer housing is made from welded steel construction and delivered with external insulated steel sandwich panel casing, making it suitable for outdoor installation. The system includes:

Perforated sheet board internal floor

Steel roof panel extension

Compact layout that does not require large installation space

Drying Process

The Hotbox dryer operates with a hydraulic power pack, driving walking floor bars that move the material across the drying decks. Key features include:

High-efficiency axial fans with lightweight composite blades

Automatic fan speed control via frequency inverter

Optimized airflow and drying agent temperature regulation

Control System

The dryer is equipped with an advanced automation system featuring:

Touch display interface for local operation and process visualization

Remote access via PC, mobile phone, or tablet

Integrated biomass moisture monitoring

Equipment & Features

Each dryer comes fully equipped, including:

All required sensors and measuring devices

Hot air generator with flow and return pipe connections

Safety valves, temperature and pressure controls

Adjustable drying bed height

High-quality components from leading global manufacturers

Thanks to the expertise of our engineering team, Hotbox dryers achieve some of the highest energy efficiency levels in their class.

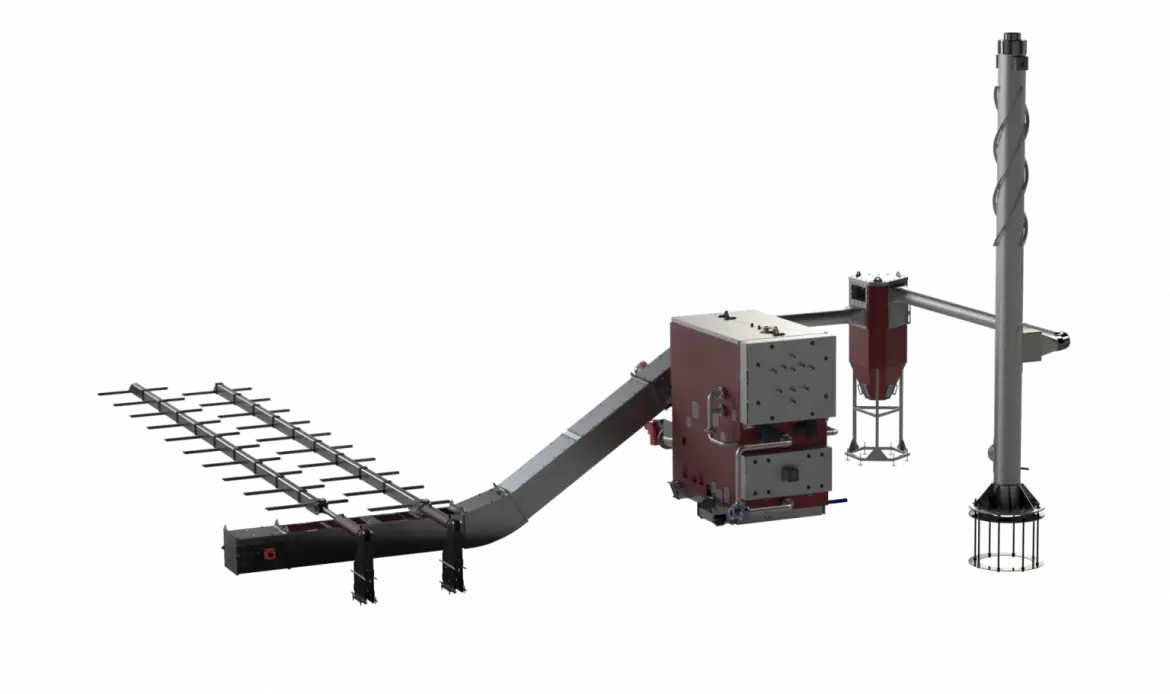

Biomass boilers

Efficient combustion, simple maintenance, and fuel flexibility — built for real heat needs.

Biomass boilers

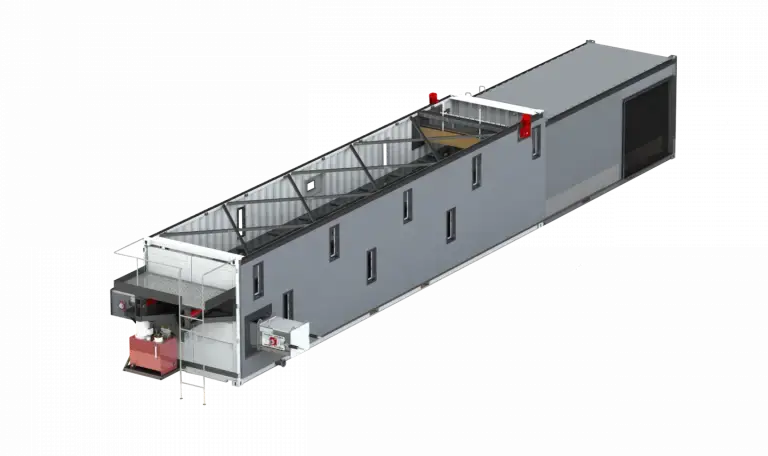

Mobile containerized boiler houses offer a fast and flexible solution for solid biomass heat production. These systems are designed for easy on-site installation, minimizing project time and cost. Fully equipped with automatic combustion, fuel feeding and ash extraction, they are ideal for remote heat supply and can be monitored online from any smart device.

Applications

Mobile containerized boiler houses are suitable for:

District and local heating networks

Industrial process heat supply

Agricultural and greenhouse heating

Temporary or emergency heat source needs

Remote locations without existing boiler infrastructure

Thanks to their mobility and fast setup, they are especially useful in projects with time or space constraints.

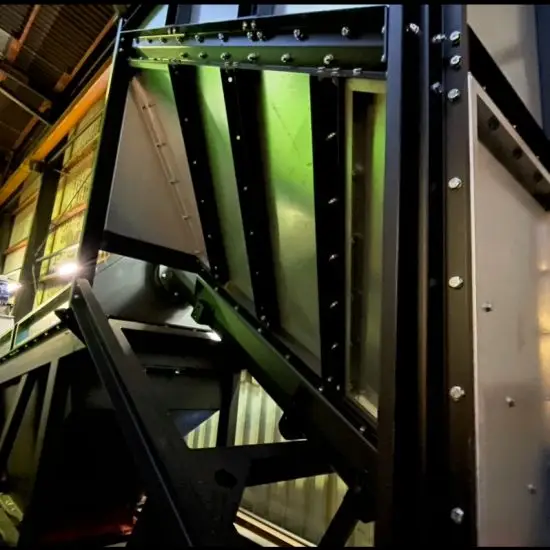

Design

The system consists of a mobile container-type boiler house, equipped with:

- Moving grate furnace

- Water heating boilers

- Multicyclone dust separation unit

Compact container design allows for quick installation almost anywhere, reducing the need for extensive construction work.

Power and Performance

Thermal power output starts from 200 kW

Maximum water temperature up to 110 °C

Operating pressure up to 10 bar

These specifications make the system suitable for various mid-size industrial and municipal heating needs.

Fuel and Combustion

The system is designed for bulk solid biofuel with a moisture content between 10–55%. The complete combustion setup includes:

Automatic fuel feeding mechanism

Moving grate furnace for efficient combustion

Multicyclone for flue gas cleaning

Lambda probe for automated combustion process optimization

Automation and Control

Containerized boiler houses are available as fully automatic systems, featuring:

Automatic ash extraction

Remote monitoring and management via internet

Compatible with PC, Mac, and smart devices

Key Advantages

Fast installation – ready-to-use systems reduce on-site construction time

Compact design – containerized layout minimizes required footprint

Flexible relocation – units can be moved and reinstalled elsewhere

Fuel flexibility – handles biomass with varying moisture levels

Remote access – full control and monitoring from any smart device

Cost efficiency – reduced project development and operation costs

Our

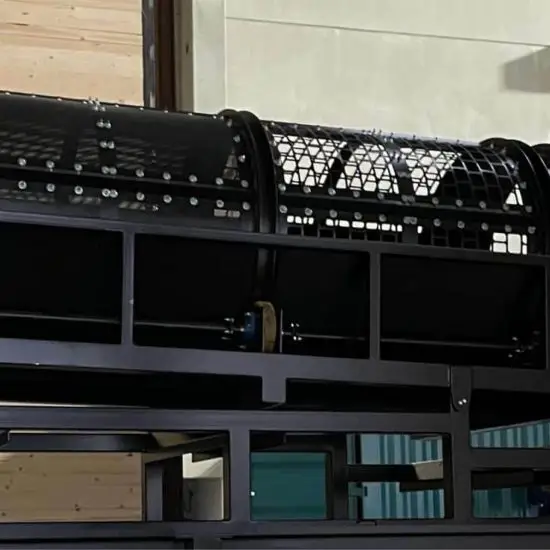

Conveyors and Moving Floors

Reliable conveyor and moving floor systems for efficient material handling.

Green Energy Systems designed moving floors and conveyor systems.

Chain conveyors and screw conveyors, designed for various kinds of loose biomass, grain or ash transportation, offered in a variety of capacities as well as different length, width, diameter variations.

Modular moving floors on concrete base or built in steel containers as biomass storage where the hydraulic drive moves biomass towards the extraction conveyor.

Bunkers, containers, drum sieves and vibrating table type sieving units.

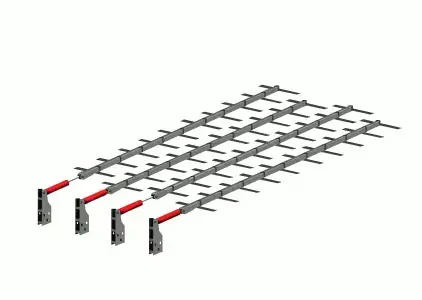

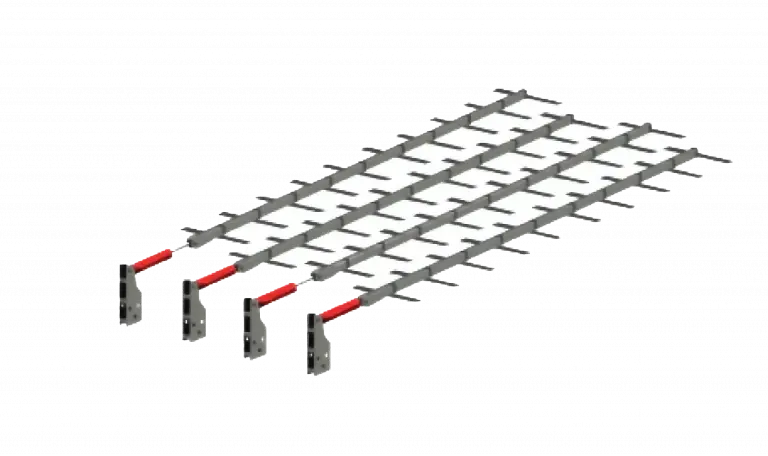

Moving floors

Used for

- Scraper bar moving floor storage is a good option to store bulk materials with an option to discharge material over transverse chain conveyor.

- It’s also used in our biomass dryers.

Design

The scraper bars are moved by hydraulic cylinders which are powered by hydraulic powerpack.

Robust design and high quality components, ensure necessary operational reliability.

Process

- The scraper bars are moved by hydraulic cylinders which are powered by hydraulic powerpack.

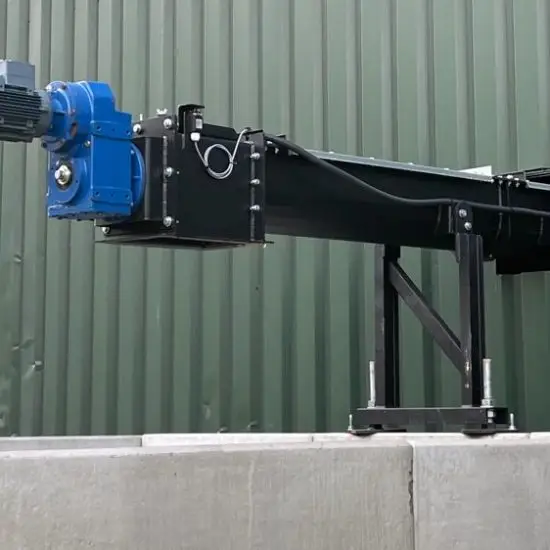

Chain conveyors

Used for

Chain conveyors handle a wide range bulk materials. The robust design and efficient utilization of space means the conveyor take less environmental space.

Design

- Chain conveyors have chain with feed plates which runs in a closed conveyor’s body

- Depending on the design of the feed plates materials can be conveyed horizontally or inclined.

- Materials can be conveyed in the lower deck run as well as the upper deck run

- Multiple unload hatches are available

- Suitable for transporting different bulk materials

- Chain conveyor moves material distances ranging from 3 -100 meters or more

- Conveyors is equipped with the extremely durable chain.

Belt conveyors

Used for

Belt conveyors handle a wide range of bulk materials such as wood chips, bark, pellets, RDF, SRF, grains, sand and similar free-flowing materials. They are suitable for both horizontal and inclined transport over short and long distances. Commonly used in biomass energy systems, wood processing, waste handling and agricultural industries.

Design

The belt conveyor consists of a welded steel frame with support legs, drive and tail pulleys, belt tensioning unit and safety protection covers.

Conveyor belt is selected based on the transported material’s properties – such as abrasion resistance, temperature tolerance and material flow behavior.

Equipped with wear-resistant liners in high-friction zones.

Belt speed and drive power are selected according to the required capacity.

Dust covers or closed housing available for dusty or outdoor applications.

Easy integration with other material handling systems like feeders, hoppers or screening units.

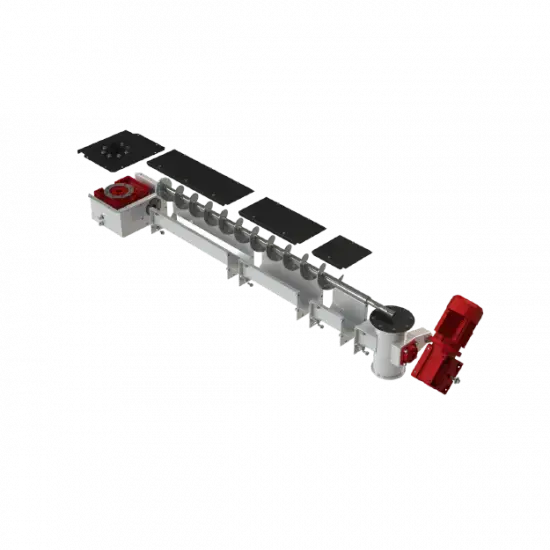

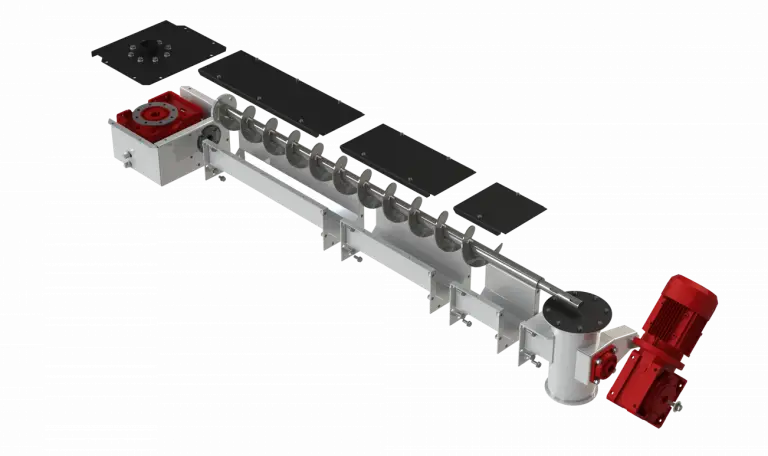

Screw conveyors

Used for

Screw conveyors are used for dosed and continuous transportation of bulk materials, granular materials

woodchips

wood shavings

bark

peat

sand etc

Installation can be horizontal or at an incline.

Design

Simple, compact, robust design

The material to be conveyed can be loaded at any chosen position Individual choice of materials and wear lining on request

Installation can be horizontal or at an incline.

Long service life, low maintenance.

Delivery rate

- up to 150m³/h

Conveying diameter:

40 to 500mm

Bulk Material Storage Solutions

Storage hoppers offer a reliable and space-efficient solution for bulk material handling and storage. Designed for industrial use, these sealed units ensure clean operation, easy maintenance and long-term durability. With a modular structure and flexible volume options, they can be adapted to meet specific project needs.

Storage hoppers for bulk material storage

Used for

Storage hoppers are designed for storing various types of bulk materials, such as biomass, pellets, bark, RDF, SRF and other free-flowing materials. Their compact and modular construction makes them suitable for a wide range of industrial applications.

Design

These storage units feature a fully sealed, dust-proof body that ensures a clean working environment and safe material containment.

Volume range: 5–200 m³

Simple, compact, and robust steel design

Easy access for inspection and maintenance

Long service life with low maintenance requirements

Wear protection and custom material selection available upon request

Modular setup allows flexible integration into existing systems

Equipped with high-quality components, these hoppers provide the reliability required for continuous industrial operation.

Screening Solutions

Storage hoppers offer a reliable and space-efficient solution for bulk material handling and storage. Designed for industrial use, these sealed units ensure clean operation, easy maintenance and long-term durability. With a modular structure and flexible volume options, they can be adapted to meet specific project needs.

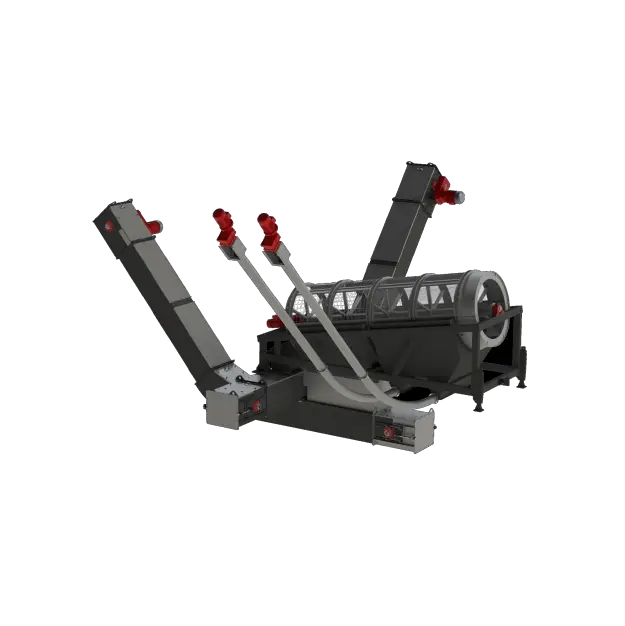

ROTARY SIEVE

- Capacity: up to 100 m³/h (depending on fraction size)

- Separates up to 4 different fractions

- Delivered in a sealed 20′ container

- Compact, robust construction for easy integration

- Optional wear liners and material configurations

- Long service life, minimal maintenance

VIBRATING SIEVE

- Capacity: unlimited (project-specific design)

- Modular, compact construction for any setup

- Ensures continuous operation with low downtime

- Easy access for cleaning and servicing

- Durable components for intensive industrial use

- Long service life, minimal maintenance

Steel structures & Supports

General construction & Structure steel

Industrial buildings made to perform.

We design, manufacture and install structural steel buildings for a wide range of industrial needs — not only as part of our energy projects, but also as independent construction services.

From biomass storage and boiler houses to production halls and utility buildings, our team delivers turnkey solutions that are functional, durable and easy to maintain.

What we build:

Steel halls for storage and production

Boiler house envelopes and equipment shelters

Conveyor tunnels and pipe bridges

Steel framing for process zones and service platforms

Load-bearing structures for biomass or waste systems

Custom industrial buildings on request

Even when the structure isn’t the most complex part of the project, we build it with the same precision as everything else we do.

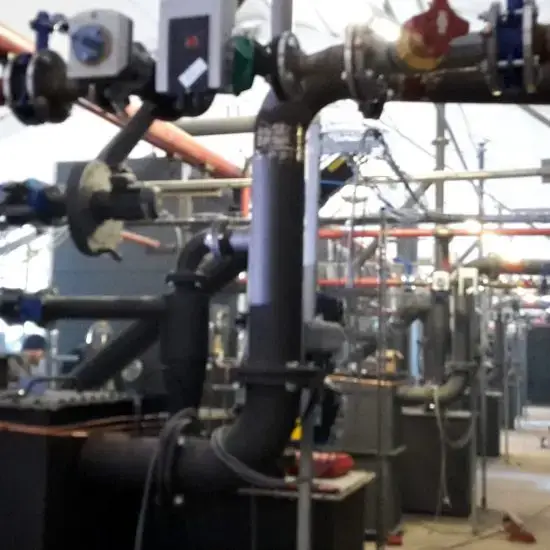

Pipework

Built to handle pressure — and responsibility.

Our welders and fitters install process pipework for all types of industrial systems. Whether it’s gas lines, exhaust routing, or hot water distribution — we build systems that are safe, efficient and made to last.

We take care of the full installation process, from welding and support frames to thermal insulation and pressure testing, always with attention to function and long-term durability.

We work with:

Gas piping for CHP and flare systems

Exhaust and air flow routing

Hot and warm water pipelines

Biomass and sludge transport lines

Structural supports and pipe bridges

It’s not just about connecting points — it’s about making the whole system work.

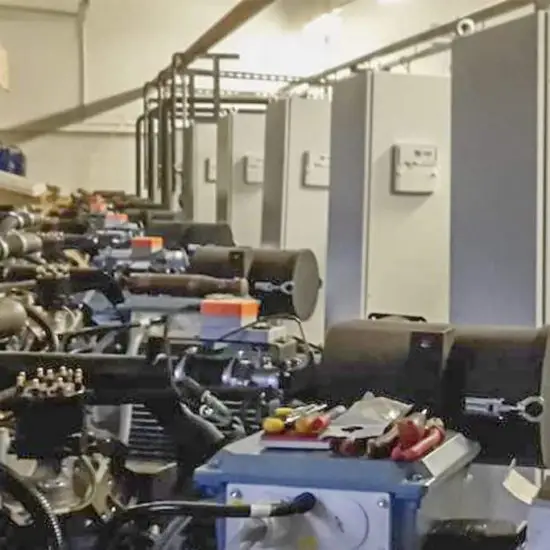

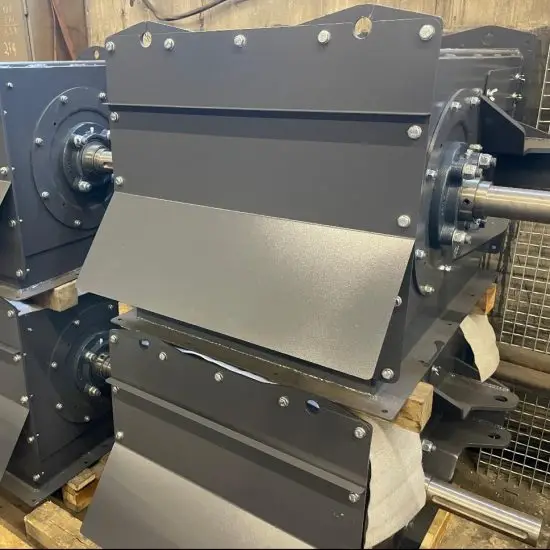

Hydraulic Driven Units

We supply the drive — not just the structure.

Green Energy Systems designs and delivers complete hydraulic drive units for industrial systems. Our hydraulic sets are used to power conveyors, moving floors, dryers, push floors and more — wherever strong, steady movement is needed.

We don’t just install equipment. We supply the drive system that makes it work.

Hydraulic units available for:

Moving and push floors

Biomass dryers and feed hoppers

Custom material handling setups

All units are configured for each project and built to handle heavy-duty loads in tough conditions.

Hot air generators

Not the small kind.

We supply high-capacity hot air generators built for industrial drying systems — biomass, RDF, sludge and more. Designed for integration into dryers, kilns or heat zones where controlled air temperature and flow matter.

These are not portable heaters. They are made to deliver steady, high-volume hot air, day in, day out.

Used in:

Biomass dryers

Belt and thin-layer drying systems

Sludge treatment plants

Thermal process zones in energy systems

Custom-sized, fuel-adapted, and built to run as part of a full system.

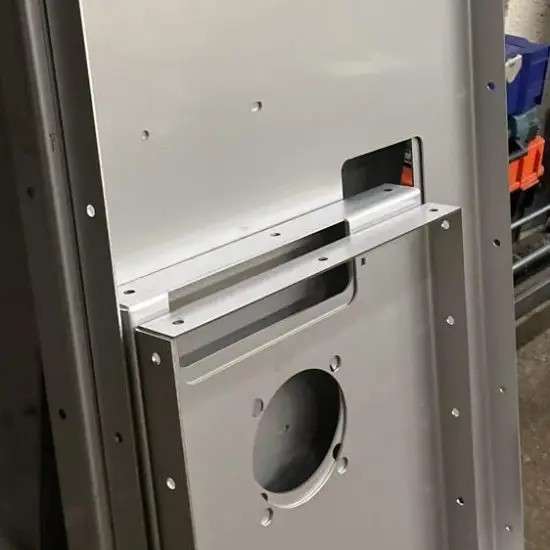

We don’t outsource strength — we make it.

Built in Steel

From precision-cut parts to welded assemblies, we produce structural and mechanical components for energy systems and heavy industry. Made in-house. Built to last.

Laser cutting for steel, stainless and galvanized sheets

Cut Clean, Cut Precise

Our in-house laser systems handle high-volume, high-accuracy cutting for projects that demand speed and consistency.

MIG/MAG, TIG, arc — structural and functional welds

Held Together Right

From frames and assemblies to pipework and tanks, we weld for durability. Our work holds under pressure — literally.

Where precision meets performance.

Steel Components & Equipment Services

We don’t just work with steel — we shape it to serve real industrial needs. From raw material to finished system, Green Energy Systems delivers full-cycle metalworking services that stand up to time, pressure, and daily use.

Whether it’s a single component or a full structure, we build it with care, experience and the right tools — and we make sure it fits into your process from day one.

Metalworking

Reliable execution from start to finish.

Metalworking Services

We provide industrial-grade metalworking for projects that demand accuracy and durability. Our in-house production covers all the key processes.

Precision starts here

Laser Cutting

We use high-power laser systems to cut carbon steel / mild steel , stainless and galvanized sheets — clean, burr-free and dimensionally accurate.

Capabilities:

Carbon steel, stainless, galvanized

Fine details and complex shapes

High-volume and one-off cuts

Sharp edges, no finishing required

Accuracy in every angle.

Bending & Folding

Using CNC press brakes and roller presses, we bend and fold metal sheets into precise, functional forms — from simple flanges to complex profiles.

Capabilities:

CNC-controlled repeatable accuracy

U-shapes, boxes, complex geometries

Tight radii and long-length bending

Ideal for enclosures, panels, frames

When shape and fit matter.

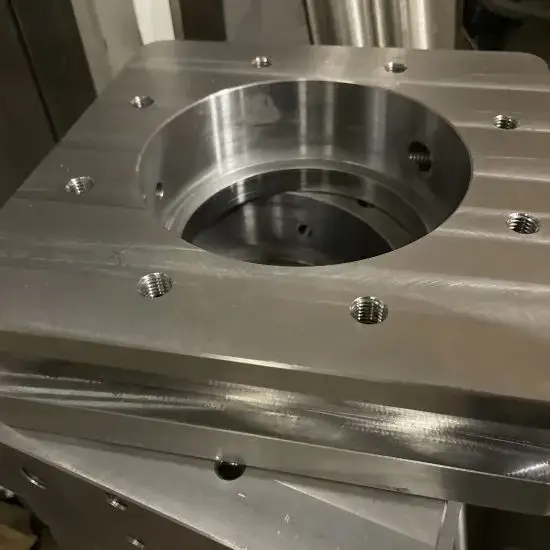

Machining

Our rounding and milling machines allow us to produce precise shapes for shafts, bearing housings, sprockets, pins and other key components.

Capabilities:

Turning, milling, drilling

Precision parts in steel, stainless or aluminum

Low to medium volume

Shafts, bearing housings, sprockets, pins, etc.

Built to hold under load.

Welding

Our certified welders assemble metal structures, frames, piping and machinery using MIG, MAG, TIG and arc welding methods.

Applications:

Equipment frames and structural supports

Pressure-bearing pipelines and tanks

Heavy-duty joints and mechanical seams

Welded assemblies and substructures

Protection that lasts.

Shot blast / Painting

We offer surface finishing for all metal parts to ensure corrosion resistance, weather protection and visual quality.

Options:

Industrial painting systems

Hot-dip galvanizing

Coating thickness on request

Suitable for indoor or outdoor use

Fitted, welded, and tested.

Pipework

We manufacture and install process pipework for gas, water, exhaust and biomass systems — from raw pipe to complete layout.

What we do:

Pipe cutting and profiling

Pipe welding and assembly

Flanged, threaded or welded joints

Support frames and routing bridges

Installation

Not just delivered — installed, adjusted, and ready.

Assembly & Installation

We take projects beyond production with full mechanical setup on-site. Our teams handle equipment assembly, adjustment and testing, making sure everything runs as expected.

On-site equipment assembly

Mechanical installation and adjustment

Warranty and post-warranty service

Spare parts and technical support when needed

We don’t leave with a delivery note — we leave when the system works.

Various nonstandard equipment

Engineering

Engineering services

Engineering for Biomass and Waste Systems

Green Energy Systems provides full-cycle engineering services tailored for biomass and waste-to-energy sectors. We design and develop equipment for biomass handling, drying systems, power plants, and heating plants — all built for long-term efficiency and integration into industrial environments.

Custom Solutions for Complex Facilities

Our expertise extends to MSW (Municipal Solid Waste) and all grades of wood waste sorting and processing plants. Whether the material is raw, recycled or mixed-grade, our engineers develop process flows and layouts that match each project’s unique requirements — from feedstock intake to final energy output.

Turnkey Projects and Operational Support

We specialize in turnkey installations, covering everything from design and production to delivery, on-site assembly, and commissioning. Beyond installation, we also offer plant operation services and technical training for client personnel — ensuring long-term performance and independence in daily operations.