Dryers

USED FOR:

Green Energy Systems dryers ar used for

biomass, RDF, SRF waste, wastewater sludge and wood chip drying.

DESIGN

-

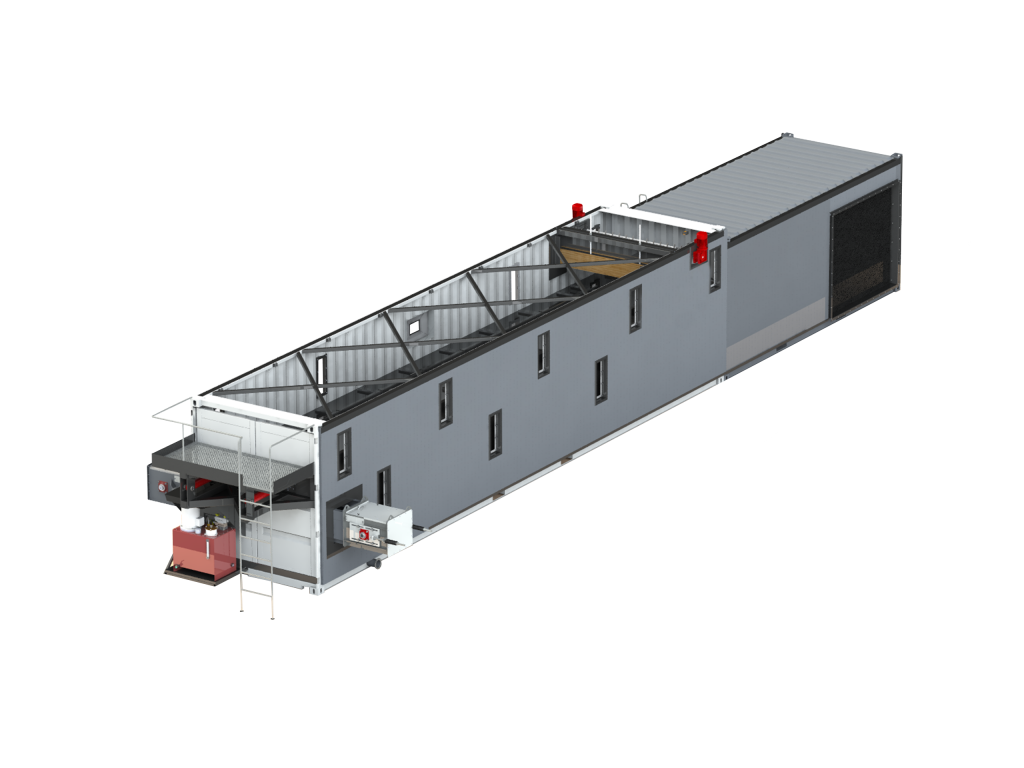

The housing of the dryer is welded steel construction.

-

The internal floor is made of perforated sheet board.

-

The dryer is delivered with an external insulated steel sandwich panels casing.

-

With this housing the dryer is suitable for outdoor installation and is equipped

with a roof extension made of steel roof panels.

PROCESS

-

The Hotbox dryer is driven by hydraulic power pack, which moves the bars as the walking floor – moving the material over the drying decks

-

The Hotbox is equipped with very efficient axial fans, which propeller blades are made of light composite casting material

-

Using the frequency inverter, the automation system adjusts the fans rotational speed to keep the desired drying agent temperatures

CONTROL

-

The control system is equipped with a touch display for operation and visualization of the Hotbox dryer

-

Remote control via PC or mobile phone or iPad is possible including the visualization of drying processes interface

EQUIPMENT

-

The dryer is fully equipped and setup Includes all measuring devices and extension of control system.

-

Dryer hot air generator is equipped with suitable flow and return pipe work connection flanges, valves, safety group, temperature and pressure control

-

Adjustable height of drying bed is installed.

Other equipment:

Hoppers for bulk material handling;

Click to the link and watch the video about our equipment.